It strikes a delicate balance between having enough to meet demand and not so much that your storage is overflowing with unused products. Finally, safety stock is the number of items that companies keep in stock to guard against stockouts that may occur due to sudden shifts in supply and/or demand. If the delivery of an item is delayed or the consumption rate increases rapidly and unpredictably for any reason, the safety stock will cover the shortage of items. Reorder point planning is an early approach to supply chain planning; however, while often dismissed as passé, it has applicability in several circumstances. Reorder point planning can rop meaning business be used effectively for products that are easy and difficult to forecast.

Life Cycle Management

A reorder point, or ROP indicates an inventory item’s minimum stock level at which new stock should be ordered in order to avoid a stockout. In other words, the reorder point is the lowest number of units of an SKU that a company needs to have in stock to make sure it can keep fulfilling orders. It can Balancing off Accounts thus also be viewed as the last time to replenish stock to avoid a stockout. ROP is essentially the normal consumption of inventory during average lead time plus some safety stock if the lead time or inventory usage are variable. This type of simple “requirements planning” technique has been used for many years.

Basic safety stock formula

If your suppliers supply raw materials on time, your production process does not disturb you. Now we use historical data to determine the standard deviation of lead time. Over time, it may be necessary to make adjustments to your ROP as a result of shifts in demand, lead time, or safety stock requirements. This system monitors your inventory levels and orders more when the level drops below a certain point. Reorder points typically include safety stock, as demonstrated in the previously discussed formula. Even if it is not explicitly stated, it is advisable to incorporate some allowance to account for unexpected events.

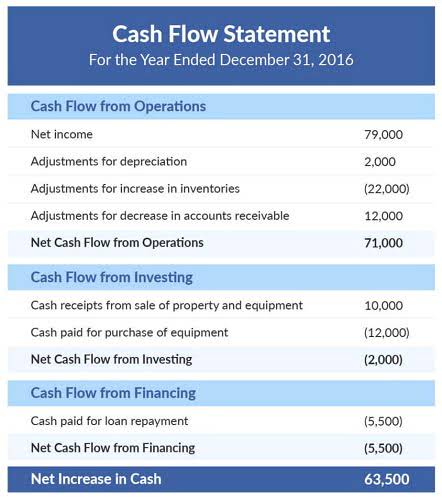

- By maintaining lower, efficient inventory levels, the company optimizes cash flow, freeing up funds for other investments.

- It’s based on historical demand variability, lead times, and its importance to the business.

- Safety stock and the order point in inventory management are equally important.

- Unlike EOQ which is concerned with how much of inventory is to be ordered, the reorder point determines when the order for inventory is to be placed.

- This protection is vital even if the supplier is late or customer demand spikes before the new shipment arrives.

Partner Activation

- By using the most optimal reorder levels, businesses can keep storage and warehousing costs low to protect profits.

- By considering both the expected demand during lead time and the safety stock, it provides a cushion against uncertainties while avoiding excessive inventory.

- Higher service levels, such as 99%, require a greater quantity of safety stock compared to a lower service level, such as 90%.

- If your supplier consistently delivers on time, then you have tighter control over inventory levels, which translates into an uptick in supply chain efficiency.

- A standard, non-tiered payment given to partners per transaction or referred customer.

This issue is one example, but there are many more questions and ways of optimizing supply planning by addressing questions just like this one for each company. If this is something you are interested in, contact us at the chat widget in the lower right hand corner, or at So, they establish a reorder point to trigger a new order when inventory drops to a certain level. This formula considers costs related to setup, production, and storage, as well as other factors that include demand.

For a reasonable measure, take an average of the past three months of POs for the SKU item you want to set a reorder point for. In eCommerce, where customer satisfaction hinges on the seamless availability of products, mastering inventory management is necessary. A staggering 4% of annual sales are lost on average due to stockouts, yet overstocking, while appearing as a safety net, can https://bfor.es/2025/06/23/what-are-the-errors-not-disclosed-by-the-trial/ silently erode your profits with rising holding costs. This is where Re-Order Point (ROP) becomes a game-changer for eCommerce brands. Their supply is relatively unconstrained, and their lead times are short.